Software to revolutionise manufacturing launched in Yorkshire

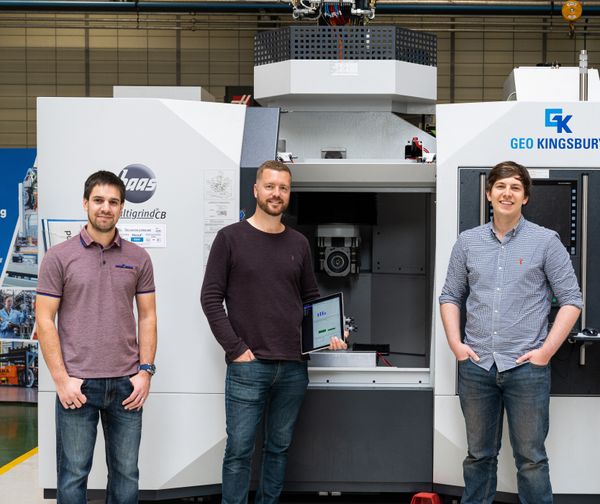

New software dubbed the ‘Fitbit for manufacturing’ has been developed by FourJaw Manufacturing Analytics, a new tech start-up that has grown out of the University of Sheffield’s globally recognised Advanced Manufacturing Research Centre (AMRC).

This new Manufacturing Execution System, which is now being tested with Yorkshire companies, will help UK manufactures improve shop floor productivity by unlocking Computer Numerical Control (CNC) data and insights that can be turned into actionable information.

FourJaw began as a research project with financial support from the Royal Academy of Engineering and is the brainchild of AMRC commercialisation manager Chris Iveson and machining project engineer Robin Hartley.

The team has worked with Sheffield based technology company The Curve who has increased the product usability by developing an app to present the data.

Chris said: “Many manufacturing companies are struggling to understand what is happening on their shop floors because performance is difficult to measure in any detail.

“This is why we have developed our offering as ‘software-as-a service’ which will mean firms adopt accessible data without a huge upfront cost.”

Robin added: “It’s common to find average machine utilisations of around 50% across all machines on a manufacturer’s shop floor, which makes locating a troublesome component on an individual machine a difficult task.

“The system which we have developed is a massive opportunity to augment the technical excellence of UK manufacturers with the world-beating productivity that modern technology enables.”

Paul Ridgway, CEO of The Curve added: “Productivity in the current market is key to the viability of any business, helping free up resource, lower costs and ultimately beat competitors.

“The analytic solutions FourJaw are providing are incredibly important and it’s been fantastic to help make this accessible to the market and to help them in their journey of establishing their business.”

The AMRC’s deputy head of digital, Jon Bray, says: “This is a beautiful example of what can happen when digital meets manufacturing. You can only get this kind of breakthrough when you bring really, really good software guys into close collaboration with really detailed engineering knowledge to interpret what the software is telling you. Sheffield has both these skill sets in spades.”