Brewfitt launches new initiatives to tackle industry’s energy cost crisis

As the brewing and hospitality industry struggles with rising energy costs – Brewfitt is developing more solutions to help breweries, pub companies and independents save thousands of pounds.

Industry-leading dispense solutions provider Brewfitt says that quick fixes and short-term measures are only going so far and what companies need now more than ever are both cost saving and performance improving solutions to help them to survive this latest multi-layered crisis, but also to thrive longer term.

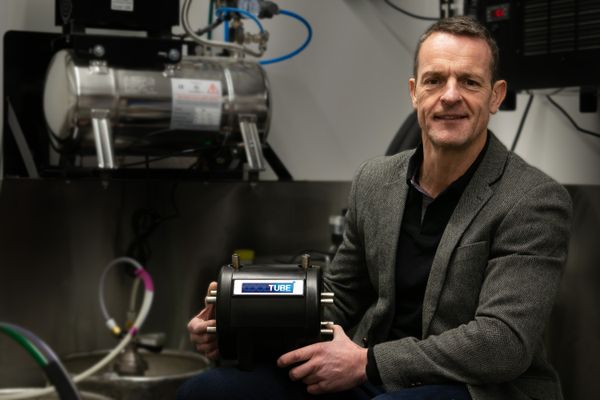

“Barely a day goes by without our industry seeing another brewery or pub close its doors. They’re victims of the mix of economic crises that have bombarded the industry for the last few years, including eye-watering rises in energy costs. Energy cost is the single biggest threat to the industry right now,” says Brewfitt Managing Director Curtis Paxman.

“And it’s unlikely to end soon. The brewing and hospitality industry has learned it can’t rely on one off initiatives or funds from the Government. Instead, companies need to look inward and modernise and adapt. Adopting new technology and ways of operating that save money and improve performance, are what will offer long-term tangible solutions that can help businesses cope with the stress of economic turbulence.”

Brewfitt works with some of the world’s biggest drinks brands and independents, including ABInBev, Bacardi, Molson Coors, Albert Schloss and Revolution bars. And it has developed a range of solutions aimed at saving breweries, pub companies and independents thousands of pounds.

Future of Dispense System

Its Future Of Dispense (FOD) system can save a typical venue up to 60% energy consumption per cooler, meaning £1,800 in annual savings for the average pub. It also reduces excess beer waste, with lines cleaned every four weeks, saving the average pub up to 1,500 pints a year during the process.

But don’t just take their word for it. The company has an online calculator so that businesses can calculate what it can save them. The FOD system is also ‘free of tie’ meaning companies aren’t tied to a particular brand or beer sales targets. This puts customers in much better negotiating positions with suppliers, wholesalers and breweries. It can be integrated with their own draught cocktail system too, tackling another industry challenge with workforce overheads.

Roxy Leisure, now one of the most successful on-trend bar groups in the country, has adopted the FOD system and plans to ‘go live’ with several more locations this year. The group’s Commercial Director Ben Jones agrees that using new technologies and looking inward to see how businesses can adapt to forces beyond their control is key to survival. He says: “FOD ticks all the boxes for us, delivering consistent quality, energy and waste savings and complete brand freedom. We’re achieving a 50% reduction in energy use compared to a traditional system. This equates to thousands of pounds per year across our sites. The savings are amplified when you consider we need less coolers, avoiding the initial outlay and running costs. Strategically it’s been the perfect solution for us, a tried and tested system that proves itself time and time again.”

App driven power saving plug in

In January, Brewfitt introduced another piece of cost-saving kit to the industry – the Energy Saviour Plug. It’s an App-driven power saving plug in, designed specifically for beer and soft drinks coolers and can cut energy bills by around 30%. It's an inexpensive piece of kit costing £125, that Brewfitt themselves use and has reduced their energy bill by 35%.

Curtis adds: “It’s another example of how energy saving can be achieved with long term benefits. We’re always looking at ways to improve system efficiency without compromising on quality.”

Now is the time for businesses to look at their own operations and identify where they can improve, says Curtis. Recently another customer contacted Brewfitt about replacing their existing draught beer dispense system. They were paying over £1,800 per year in energy costs for a single cooler. The energy saving benefits of the FOD system negate the need for that cooler, meaning the entire system will be paid back in less than three years based on that cooler saving alone. The customer owns the FOD system too, which means they’re free of tie. Other energy cost saving initiatives focusing on dispense include beer coolers, cellar cooling and bottle cabinets utilising their fridge and cellar manager devices.

Curtis adds: “We want to help businesses to save money, operate more efficiently and improve their performance. It’s about more than surviving – we want pubs and groups to survive and be able to thrive – withstanding whatever comes in future.”